New Perspectives for Urban Spaces

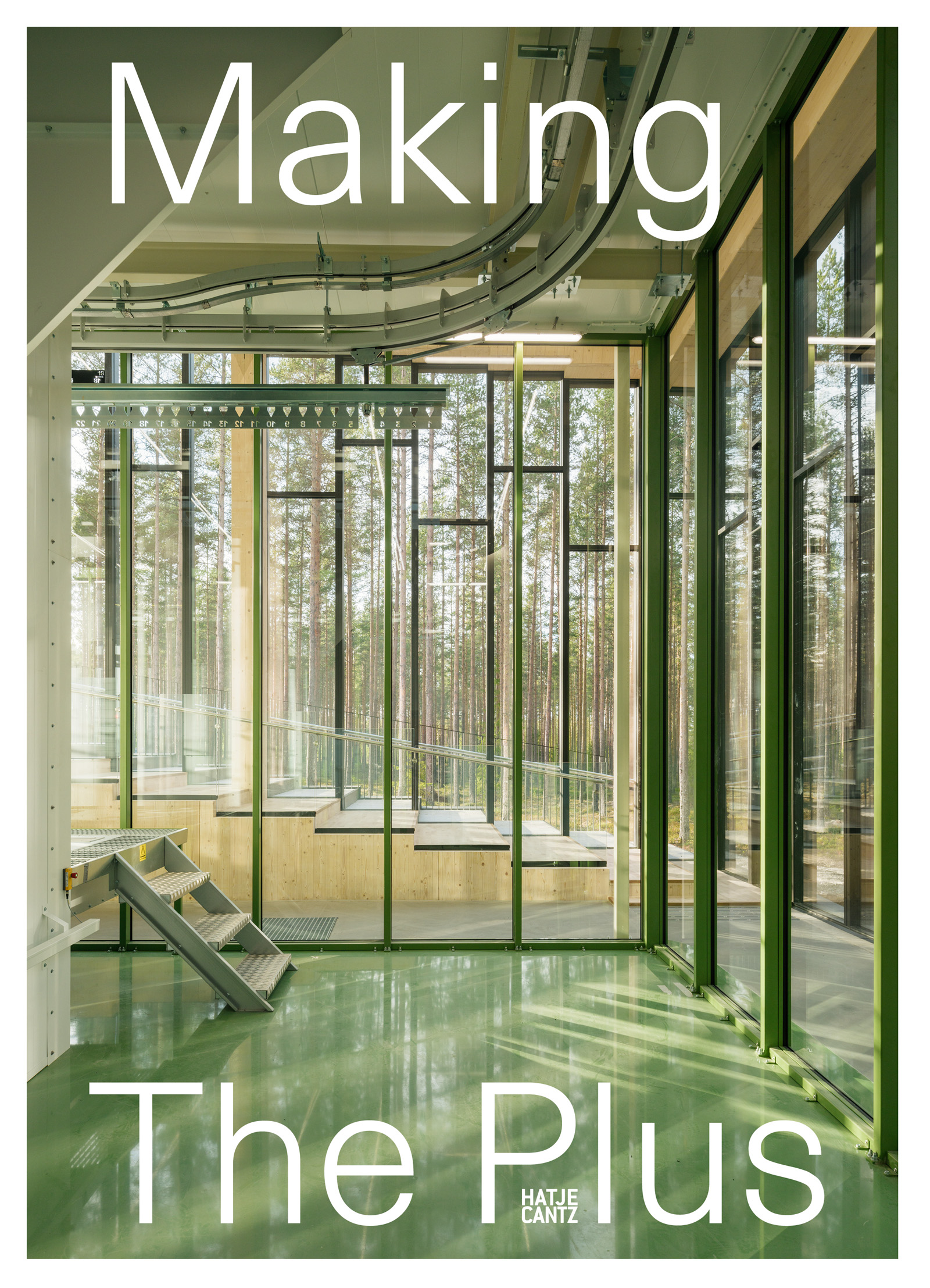

The large building with its black wooden facade looks like a spaceship has landed in the middle of a forest. It is located on the outskirts of Magnor, a village in Norway. Since 2022, ‘The Plus’ has served as the headquarters, production site and visitor centre for the family-run company Vestre. It was designed by the Danish architectural firm BIG (Bjarke Ingels Group). The building attracts those curious about the origins of Norway’s iconic urban furniture, which is well known in Norway and among the population of neighbouring Sweden. It also draws visitors interested in seeing how a manufacturing facility can operate with unmatched levels of transparency and sustainability.

The World’s Most Environmentally Friendly Furniture Factory

‘The Plus’ is a step towards a climate-neutral future and a role model for other industries that will have to address the same fundamental issues in the coming years. How can we move away from climate-damaging emissions? And how can economic growth be achieved without a proportional increase in environmental impact?

Some of the answers can be found in the factory’s architecture. Built according to passive house standards, it has a low-carbon concrete structure with recycled steel reinforcement, but it is primarily made of solid timber featuring a charred wood façade which stores 1,400 tonnes of CO₂. Nearly 900 solar panels on its green roof supply the plant with electricity. Heating is provided by geothermal energy and heat pumps that harness waste heat from the machinery. 95 per cent of the water used in production is recycled. Sawdust and wood chips are burned in the local biomass plant. Thanks to its pioneering approach, the building has received a ‘BREEAM Outstanding’ rating, making it the world’s most eco-friendly furniture factory.

Imitation Encouraged

Remarkably, Vestre is extremely open about its operations. In fact, multiple tour groups arrive several times a week. Visitors, including school groups, are guided through the production areas arranged around the central courtyard of the building’s four wings: powder coating, wood processing, assembly, and warehousing and dispatch. A particular highlight is the rooftop terrace, which is open to the public at all times in keeping with Norway’s “right to roam” and offers a panoramic view at treetop height. Visitors can then make their way back down through a spiral slide, which, metaphorically speaking, takes them back to Vestre’s origins.

The company’s journey began with the production of playground equipment, including slides, in the coastal town of Haugesund, where it was founded in 1947. Just two years after the end of the Second World War, at a time when poverty-stricken Norway was struggling to rebuild, Johannes Vestre (1910–2003), a seaman and mechanic, started manufacturing functional metal items in a former military facility. Urban planners commissioned him to build playground equipment, first for the local park and then for Bergen and many other parks nationwide. This was followed by waste bins and, eventually, park benches, which are now the company’s core business, with operations across the globe.

Making Lifecycle Costs Measurable

Vestre likes to highlight how its iconic designs help to shape urban meeting places, from small Norwegian towns to New York’s Times Square. The company also underscores its commitment to environmental issues, a commitment evident in the factory itself. Those who choose Vestre products for public spaces, schoolyards or housing developments can be confident that they are benefiting from the highest sustainability standards, given that around 90 per cent of the value chain remains in-house. Steel is processed at the company’s own plant in nearby Torsby, Sweden. All timber, including pine, Kebony oak and white ash, is FSC-certified. The colourful powder coating of aluminium and steel components uses only solvent-free paints.

Around 500 products in Vestre’s range bear the Nordic Swan Ecolabel, one of the world’s strictest environmental certifications. Environmental Product Declarations (EPDs) with data on CO₂ emissions and energy consumption are available for every product. In addition, Vestre’s durability guarantee provides a clear basis for calculating full lifecycle costs.

A Fossil-Free Future

In 2024, Vestre took another step forward by becoming a global pioneer in the industrial-scale use of fossil-free steel, alongside car manufacturer Volvo. Supplied by the Swedish company SSAB, this steel replaces coal and coke in the production process with hydrogen from fossil-free sources. The first product made from this material that is identical in quality to conventional steel is the ‘Tellus’ bench, designed by Swedish designer Emma Olbers. Olbers’ work consistently aims to remain within the planet’s ecological limits.

From this year onwards, more products can be ordered in fossil-free steel. Vestre’s plans are ambitious: while currently only a tiny fraction of its range uses this low-emission material, the aim is for the entire collection to be produced from it by 2030. The aim is to reduce CO₂ emissions associated with the steel used by three-quarters. For a company that works almost exclusively with steel (aside from timber), this would be a major accomplishment. It would also provide cities, municipalities and property developers with a solution to the challenge of creating liveable urban spaces without passing the climate costs of production on to future generations.

Sustainable by Design

Could steel be replaced altogether by materials that require less energy to produce? ‘The combination of durable steel and certified timber is part of our brand’s design DNA,’ explains Julia Pültz, Managing Director of Vestre GmbH, whom we meet at the company’s German headquarters in Berlin-Mitte. ‘Our focus is on ensuring our furniture lasts for decades and can be repaired for decades to come if necessary.’ Efficient transport is also a key factor. If a city does decide to replace the furniture after many years, Vestre offers a take-back service to refurbish the products and install them elsewhere.

The company also signs maintenance contracts with city councils in Oslo and, soon, in some US cities, sending its own teams into parks to care for the furniture. Significantly, these roles are filled by people who have been excluded from the mainstream job market for various reasons, which underlines Vestre’s commitment to social as well as environmental sustainability.

Design itself naturally plays a central role in making outdoor spaces more vibrant. Alongside benches, picnic tables, litter bins and parklets, Vestre’s portfolio includes numerous modular street furniture systems that encourage people to take a break, change their perspective and add variety and topographical interest to schoolyards. For a major school project in Berlin, landscape architect Nikolai Soyka recently developed an asymmetrical system with sloping seating surfaces that can be configured in countless ways. After seeking a suitable manufacturer, Soyka found a willing partner in Vestre and now sees his design in the company’s collection under the name ‘Unity’. The series was unveiled at this year’s 3daysofdesign event in Copenhagen. In addition to seating modules, the range includes planters and trellises, which address the urgent need in the age of climate change to bring biodiversity and cooling greenery into our inner cities, which are hopelessly sealed.

Making The Plus

In ‘Making the Plus’ Vestre and BIG (Bjarke Ingels Group) architects document the construction of the ‘world’s most sustainable factory’ in the heart of a Norwegian forest. Accompanied by photographs by Einar Aslaksen, the book illustrates how architecture, industry and public space can be reimagined together.

Published by Marianne Preus Jacobsen, Vestre AS, together with Annahita Kamali and Florian Böhm (co-editors)

Berlin, Hatje Cantz, 2024

208 pages, 170 photos

ISBN 978-3-7757-5423-1

48 Euro